Concrete milling is a vital part of many construction and renovation projects, whether you’re resurfacing floors, removing old coatings, or preparing surfaces for new materials. Choosing the right concrete milling disc is essential for achieving high performance, precision, and cost-effectiveness. The efficiency of a tarcza do frezowania betonu can be influenced by several factors that impact its performance, longevity, and the quality of the finished surface. In this article, we will explore the key factors that affect the efficiency of concrete milling discs.

To learn more about selecting the right milling discs for your project, check out this guide.

Key Factors Influencing the Efficiency of Concrete Milling Discs

- Material Quality and Composition: The type of material used to make the milling disc plays a significant role in its efficiency. Higher-quality materials, such as diamond or carbide, are more durable and perform better on tough concrete surfaces. Diamond-coated discs are particularly known for their exceptional toughness, providing longer tool life and faster material removal. It’s essential to choose a milling disc that matches the material you’re working with for optimal results.

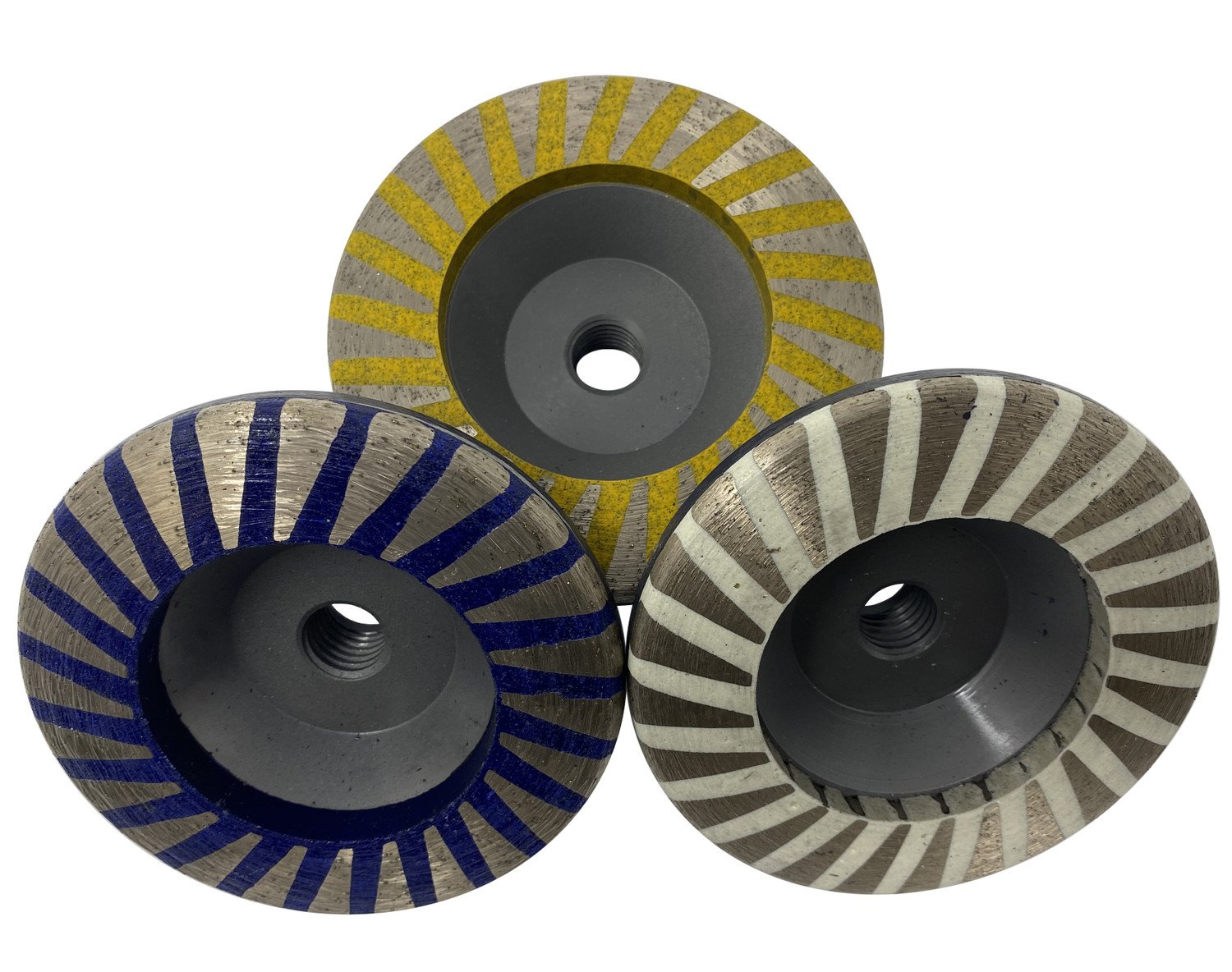

- Disc Design and Segmentation: The design of the disc, including its segmentation pattern, affects how well it can cut through concrete. Discs with a segmented design are ideal for heavy-duty milling tasks, as they provide more cutting edges and distribute wear more evenly. On the other hand, continuous rim discs are used for smoother, finer finishes. The design of the disc also affects the cooling and dust control, both crucial for maintaining performance and ensuring a longer lifespan.

- Milling Disc Size: The size of the milling disc influences how much surface area can be covered and how efficiently it operates. Larger discs can mill through concrete more quickly, making them suitable for larger areas. Smaller discs are typically used for more precise milling and tight spaces. The right size will depend on the specific needs of your project.

- Speed and RPM (Revolutions Per Minute): The speed at which the milling disc operates plays a major role in its performance. Higher speeds result in faster material removal, but they can also lead to higher levels of heat, which may reduce the disc’s lifespan. A balance between speed and heat generation is important to ensure efficient performance and longevity. Always use the appropriate RPM for the disc and the material you’re working with to prevent damage.

- Cooling and Dust Control: Concrete milling generates significant amounts of dust, which can impact both the efficiency of the tool and the safety of the workers. Some milling discs are designed with built-in cooling mechanisms or ventilation holes to help manage heat and reduce dust. Discs with dust collection systems are also available, providing a cleaner work environment and helping to maintain the tool’s performance.

- Proper Maintenance and Care: The maintenance of the milling disc can also impact its efficiency. Regular cleaning, checking for wear, and storing the discs properly can extend their lifespan and ensure that they continue to perform at their best. Additionally, using the correct tool for each specific job will prevent unnecessary wear and tear.

Conclusion

Choosing the right tarcza do frezowania betonu is critical to the efficiency and success of any concrete milling project. By considering factors such as material quality, disc design, size, speed, cooling mechanisms, and proper maintenance, you can significantly enhance the performance and longevity of your milling discs. To explore a wide range of high-quality milling discs, visit this link. Selecting the right tools for the job will not only improve your work’s efficiency but also help you achieve a higher-quality finish and longer-lasting results.